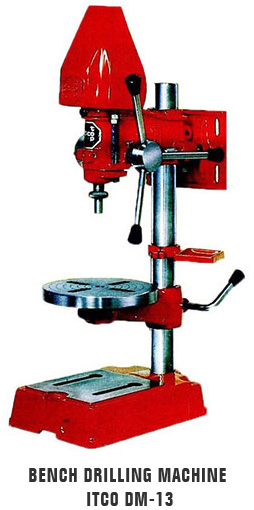

Drill Machine

Working of Drilling Machine: Drilling is a material removal operation. The component is clamped securely on the work table and the cutting tool i.e. Drill rotates at a cutting speed and is feed into the job. The material removal takes place in the form of chips.

Selection of Drill nomenclature i.e. Point angle , Helix angle and no of cutting flutes depends upto the material to be drilled. The Cutting Angle (Point angle ) can be modified whereas the latter are fixed by Drill manufacturers. For Drilling: Ferrous metals the point angle is kept as 118°, Non Ferrous Metals @ 140° and for Plastics < 80°.

Cutting speed depends upon the material to be Drilled, type of drill used, rate of Feed and depth of hole. For Drilling Ferrous Metals cutting speed reduces with the increase in tensile strength (5-8 m/min for tool steels & 20-23 m/min for mild steels). Non Ferrous Metals @ 35-105 m/min.

Feed depends upon cutting speed and drill diameter. It increases with the diameter of drill (Drill Ø 1.5mm feed @ 0.04 mm/rev, for Drill Ø 38mm & above feed @ 0.4 mm/rev)

SALIENT FEATURES OF ITCO MACHINES

- Designed and built with an expertise of more than five decades in machine tools.

- Sturdy streamlined construction enables to withstand & absorb heavy cutting forces.

- High grade alloy steel carburized, case hardened & precision ground to close tolerances used for main drive elements i.e. spindle, quill, sleeve, gears etc.

- Drill head, arm & other casting parts made from graded casting for high rigidity.

- Spindle Hardened & Ground with internal taper ground.

- Spindle Runout at final testing within 10-20 microns.

- Column made of seamless steel tube precision ground & hard chromed.

- Main gears, spindle & motor pulleys are perfectly balanced to avoid vibrations.

- 2 years Warranty.

- Table Runout (right angle) 30 to 40 microns.